In today’s construction and plumbing industries, modern pipe-fitting solutions have become central to creating efficient, reliable, and sustainable infrastructure. As projects grow in scale and complexity, professionals are turning to innovative technologies, advanced materials, and streamlined installation methods. Contractors and facilities managers alike benefit from staying informed on the latest trends, enabling them to enhance project outcomes and address ongoing maintenance concerns. For those sourcing the latest pipe fitting solutions and supplies, Cruco Mill & Industrial Supply offers a comprehensive range of products designed for modern applications.

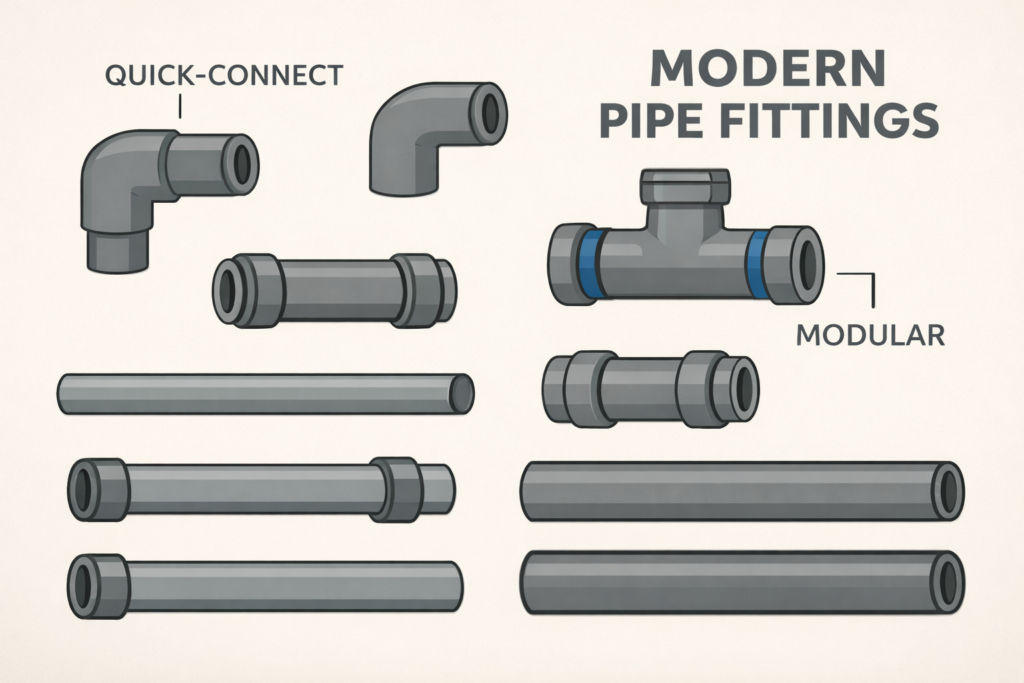

Advancements such as smart piping systems, modular designs, and quick-connect fittings reduce costs, limit installation errors, and help future-proof investments. As cities expand and infrastructure demands evolve, embracing these developments not only improves longevity but also aligns with increasingly stringent sustainability requirements. In this guide, we will explore the essential innovations shaping contemporary pipe-fitting practices and demonstrate how leveraging new materials and technologies delivers superior performance and greater environmental responsibility.

Smart Piping Systems

Technological progress has paved the way for the integration of smart systems within piping networks. The adoption of smart piping, powered by the Internet of Things (IoT), offers sophisticated monitoring capabilities. These systems feature sensors embedded directly into pipes and fittings. The sensors monitor real-time data, such as pressure, temperature, and flow rates, and instantly alert maintenance teams to anomalies. This approach greatly reduces the likelihood of undetected leaks, water damage, or costly repairs.

In industrial environments, where system uptime is critical, smart piping ensures prompt issue identification and rapid intervention. IoT-driven smart plumbing has reshaped facility management, enabling operators to predict failures before they occur and substantially reduce risk.

Modular and Prefabricated Designs

Another impactful innovation is the evolution of modular and prefabricated pipe fittings. These components are pre-manufactured in controlled factory settings, allowing for precise tolerances and rigorous quality control long before they reach the job site. Once delivered, assembly is as simple as connecting standardized modules. This not only accelerates installations but also produces more consistent results by reducing the human error that often accompanies on-site custom fabrication.

The benefits are particularly pronounced in commercial and industrial builds. Large-scale facilities can take advantage of modular assemblies that fit seamlessly together, dramatically shortening project schedules and generating significant labor savings.

Advanced Materials

Material science has brought significant advances in pipe fitting technology. The introduction of High-Density Polyethylene (HDPE) and Cross-Linked Polyethylene (PEX) has enabled plumbing systems to be lighter, more flexible, and far more corrosion-resistant than traditional materials like steel or copper. HDPE excels in harsh environments where chemical and abrasion resistance are essential, while PEX is favored for its durability and ease of installation in residential applications.

Composite materials are also seeing increased use. These combine the best properties of various substances, resulting in fittings that are not only stronger but also lighter. As the plumbing trade shifts towards these alternatives, professionals can handle, transport, and install piping more easily, further driving down costs and installation times.

Quick Connect Technologies

Ease of installation is further realized with the introduction of quick-connect and press-fit technologies. Traditional pipe fitting often involves time-consuming, specialized processes such as welding, threading, or soldering. By contrast, push-to-connect fittings and press-fit systems allow secure connections by simply inserting pipes and pressing them together until they lock in place.

These technologies have gained popularity both in the professional and do-it-yourself segments. They decrease the likelihood of leaks and lower installation costs. Products using these methods are particularly useful in tight or hard-to-reach spaces and promote safety and speed on every job site. More industries are adopting these user-friendly fittings as supply chains look to increase productivity without sacrificing reliability.

Sustainable Practices

The pipe fitting industry is increasingly prioritizing sustainability through both material selection and manufacturing practices. Modern piping products utilize recycled plastics and metals, reducing reliance on virgin resources and lowering environmental impact. Manufacturers are also integrating more energy-efficient production processes, further decreasing carbon footprints.

Additionally, many fittings and systems are now designed for easy disassembly, enabling the recovery and recycling of components at the end of their service life. These efforts align well with circular economy principles, confirming the industry’s commitment to addressing both current needs and future environmental challenges.

Conclusion

Staying ahead in the competitive fields of construction and plumbing requires recognizing and applying the latest advancements in pipe fitting. By utilizing smart monitoring, modular designs, advanced materials, and environmentally responsible solutions, today’s projects can not only meet but exceed expectations for durability, efficiency, and sustainability. Sourcing modern solutions from reputable suppliers remains essential in building tomorrow’s resilient infrastructure.