Electric motors depend on precise internal construction to deliver consistent efficiency and torque. The quality of laminated steel layers defines how effectively magnetic energy becomes motion. These layers form the core that drives performance and longevity in power systems. Let’s explore how process control, geometry, and standards guide dependable stator assemblies.

Geometric Precision in Core Design

The layout and proportions of stator core laminations set the foundation for reliable magnetic balance. Each slot, tooth, and bore dimension affects how flux travels through the core. Engineers design for symmetry to limit vibration and ensure torque stability. Computer simulations verify that every line of the drawing translates into measurable field accuracy.

Small dimensional errors can disturb air gaps and increase loss. Proper design tolerances help with mechanical alignment and temperature control. These early design checks prevent imbalance and reduce downstream correction costs.

Alloy Selection for Optimal Magnetic Response

Material choice directly influences energy transfer and heat control. Electrical steels with silicon additives minimize core loss while supporting strong magnetic permeability. Grain orientation affects flux direction, making alloy selection critical to torque output. Each sheet must maintain uniform quality to avoid irregular field paths.

Post-production heat treatment restores the alloy’s natural magnetic ability. This step removes internal stress that can limit performance. Engineers assess factors such as flux density, saturation limits, and thermal expansion before approval. The outcome is a material profile that sustains strength and conductivity over repeated duty cycles.

Precision Forming and Edge Control

The forming phase determines how accurately each sheet reflects its digital blueprint. High-speed stamping systems or fine laser tools cut profiles to micrometer precision. The die surface, clearance, and press force all shape edge quality. Clean edges reduce stray flux and improve magnetic continuity between layers.

Residual strain from forming can weaken the core’s magnetic uniformity. Thermal stabilization after shaping restores structural balance and eliminates hardened zones. Engineers confirm success by measuring core loss differences before and after heat correction.

Protective Coatings and Surface Treatment

Electrical insulation between layers is vital for efficiency. Coatings such as phosphate, oxide, or organic films create a barrier that limits eddy current flow. Each coating must adhere evenly and resist friction during stack compression. Proper selection aids both heat resistance and durability across long operating hours.

Surface finish also affects layer contact and bonding. Smooth surfaces allow uniform pressure through the stack and prevent micro gaps. Adhesion checks verify that coatings stay intact under stress and do not crack. A consistent surface layer protects performance throughout the motor’s life.

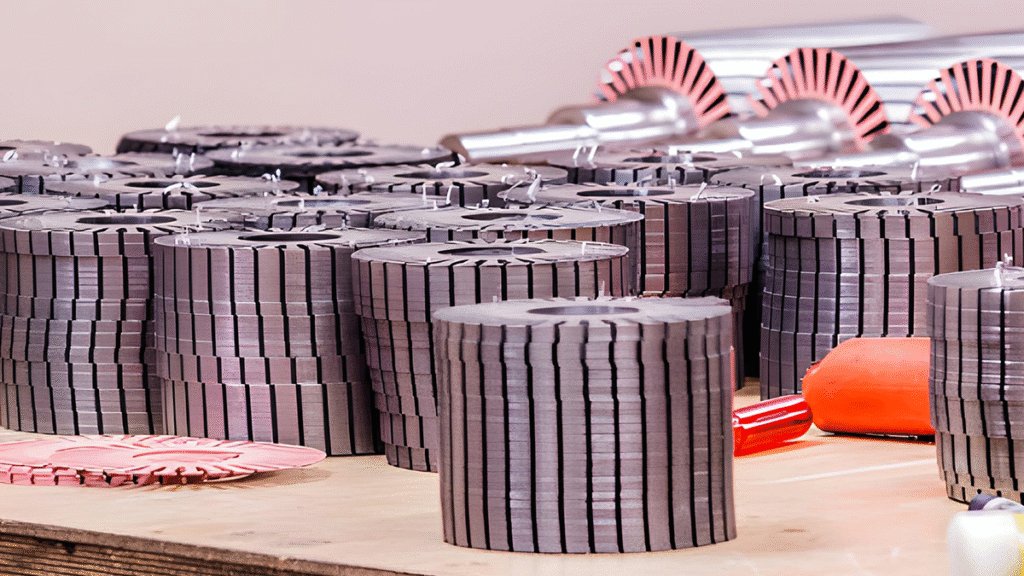

Layer Integration and Structural Assembly

Stack formation defines the physical and magnetic stability of the finished stator. Engineers may use adhesive bonding, welding, or mechanical interlocks to combine layers. Each approach controls how sheets align and hold under torque and temperature variation.

Key verification measures include:

- Height uniformity checks for stack compression accuracy

- Edge alignment tests to confirm correct geometry

- Mass balance checks for rotational consistency

- Surface inspection for coating integrity

These checks confirm that the completed core meets dimensional and magnetic expectations before installation.

Validation Standards and Testing Parameters

Quality standards guide each stage of stator production to ensure dependable results. Organizations such as ASTM, IEC, and ISO set rules for material thickness, coating types, and acceptable energy loss levels. Testing checks performance against these requirements using both electrical and magnetic methods.

Key evaluation steps include:

- Magnetic performance tests to measure flux density and core loss

- Electrical resistance checks to confirm insulation strength

- Dimensional inspections to verify layer thickness and alignment

- Thermal endurance testing to see how materials react under heat and load

- Automated data tracking for full record accuracy and traceability

Together, these steps confirm that each stator meets the required standards before use. Consistent testing and documentation ensure reliable operation in industrial and aerospace applications.

Efficiency Control and Operational Stability

Performance depends on how well a stator handles thermal and magnetic stress under load. Proper lamination thickness reduces loss and improves switching accuracy. Engineers design air channels and clearances that aid thermal management. Balanced construction reduces mechanical noise and power fluctuation.

Durability also depends on how firmly layers remain aligned under stress. Strong interlocking or bonding prevents slippage and vibration. Coatings with high heat tolerance maintain insulation in prolonged service. These combined factors may help improve output efficiency and extend maintenance intervals.

Progress in Process Innovation

Modern tools and materials continue to make stator production more precise and reliable. Thinner metal sheets with improved coatings allow stronger magnetic flow and lower energy loss. Automated machines now press and align layers evenly, which reduces mistakes. Digital sensors track each sheet’s shape and thickness as the work happens.Reliable stator core laminations stand at the center of efficient electric motor operation. From material choice to precision assembly, every step affects magnetic flow and long-term stability. Compliance with proven standards safeguards repeatable performance and energy efficiency. These refined processes help with consistent output, longer life cycles, and dependable results in modern power systems.