Machinery, vehicles, and industrial equipment represent significant investments for businesses and individuals alike. Critical to the maintenance and longevity of such assets is the use of caps and plugs—small but mighty components that shield against contaminants, moisture, and debris. These protective elements are essential in preserving the integrity and performance of systems across various industries.

Understanding the Role of Caps and Plugs in Industry

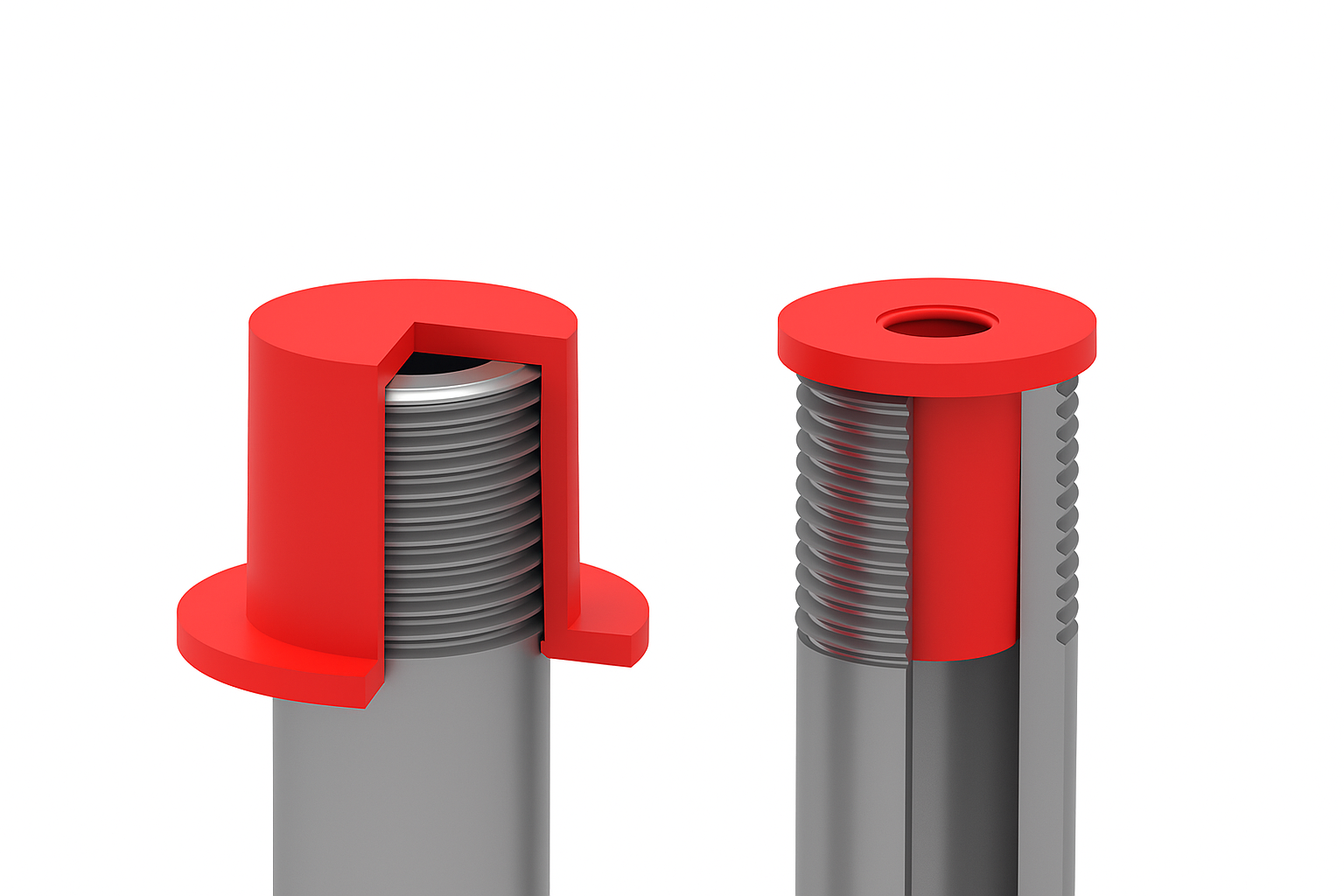

The industrial use of caps and plugs is widespread, touching nearly every sector from automotive manufacturing to aerospace engineering. These components serve the primary function of sealing off open pipes, tubes, and other conduits during storage, shipping, or processes that involve painting and coating. The absence of appropriate cap plugs can expose systems to air, dust, and corrosive substances, leading to potential damage and system failures.

While the role of caps and plugs may seem minimal at a glance, their impact on machinery cannot be overstated. By preventing foreign objects from entering sensitive components, caps and plugs maintain the cleanliness required for optimal operation. This can be particularly critical in precision-driven industries where even small particles can compromise the functionality and accuracy of complex machinery.

Furthermore, by using high-quality caps and plugs, industries can reduce the risk of costly downtime and repairs. They are much more than just simple covers; they are a vital part of a comprehensive preventive maintenance strategy that safeguards against unnecessary wear and tear on critical equipment components.

The Impact of Environmental Factors on Equipment Longevity

Environmental factors such as moisture, UV radiation, temperature fluctuations, and corrosive chemicals pose significant threats to unprotected equipment. In the absence of adequate protective measures like caps and plugs, these elements can contribute to the rapid deterioration of metal surfaces and vital internal components.

Moisture, for example, can seep into unprotected openings, leading to corrosion and rust that undermine the structural integrity of machinery. Caps and plugs help to create a moisture-resistant barrier, safeguarding sensitive parts against potential water damage, particularly in outdoor or marine settings where exposure is inevitable.

Similarly, ultraviolet light can degrade materials not suited for prolonged sun exposure, causing them to become brittle and less effective at sealing. Specialized caps and plugs are available that feature UV-resistant materials, ensuring long-term resilience and protection even in environments regularly subjected to harsh sunlight.

Temperature extremes are another consideration, as some materials can become pliable or brittle depending on the heat or cold to which they’re exposed. Caps and plugs made from quality materials formulated for specific temperature ranges are crucial for maintaining protection under these conditions, keeping equipment safe, and fully operational.

Custom Solutions: Tailoring Caps and Plugs to Specific Needs

Every industry has unique requirements when it comes to protecting equipment, and there is a growing demand for custom caps and plugs designed to meet specific needs. In industries such as oil and gas, the hostile environment demands caps and plugs that can withstand intense pressure and corrosive substances. Special materials and coatings are utilized to produce components that can endure the rigors of such demanding conditions without faltering in their protective duties.

Aerospace and medical fields also benefit from custom solutions, with strict standards for cleanliness and material integrity that generic caps and plugs may not meet. Custom-designed components ensure compatibility with the stringent regulations these industries face, contributing to safety and precision that are non-negotiable in such high-stakes environments.

The Economics of Protection: Cost-Benefit Analysis of Using Caps and Plugs

Investing in quality cap plugs is economically sound when considering the protection they offer versus the potential costs of repairing or replacing damaged equipment. The relative expense of these components is minor compared to the high price of industrial machinery and the potential loss of productivity during downtime for repairs. In essence, caps and plugs are a form of insurance against larger financial losses.

When conducting a cost-benefit analysis, the long-term savings associated with using caps and plugs quickly become apparent. Utilizing these protective components can extend the life span of equipment, reduce the frequency of maintenance needs, and minimize the risk of system failures that lead to costly stoppages and repairs.

Additionally, the use of caps and plugs contributes to safety and compliance with industry regulations, which can prevent financial penalties and legal liabilities. Ensuring that all equipment functions correctly and safely is not only a matter of operational efficiency but also of regulatory adherence, which can have significant cost implications.

Overall, caps and plugs play a critical role in ensuring that machinery and systems remain protected from a variety of environmental threats, thereby extending their usable life and saving considerable costs over time. Embracing their use is a smart and necessary strategy for any operation that relies on mechanical assets.