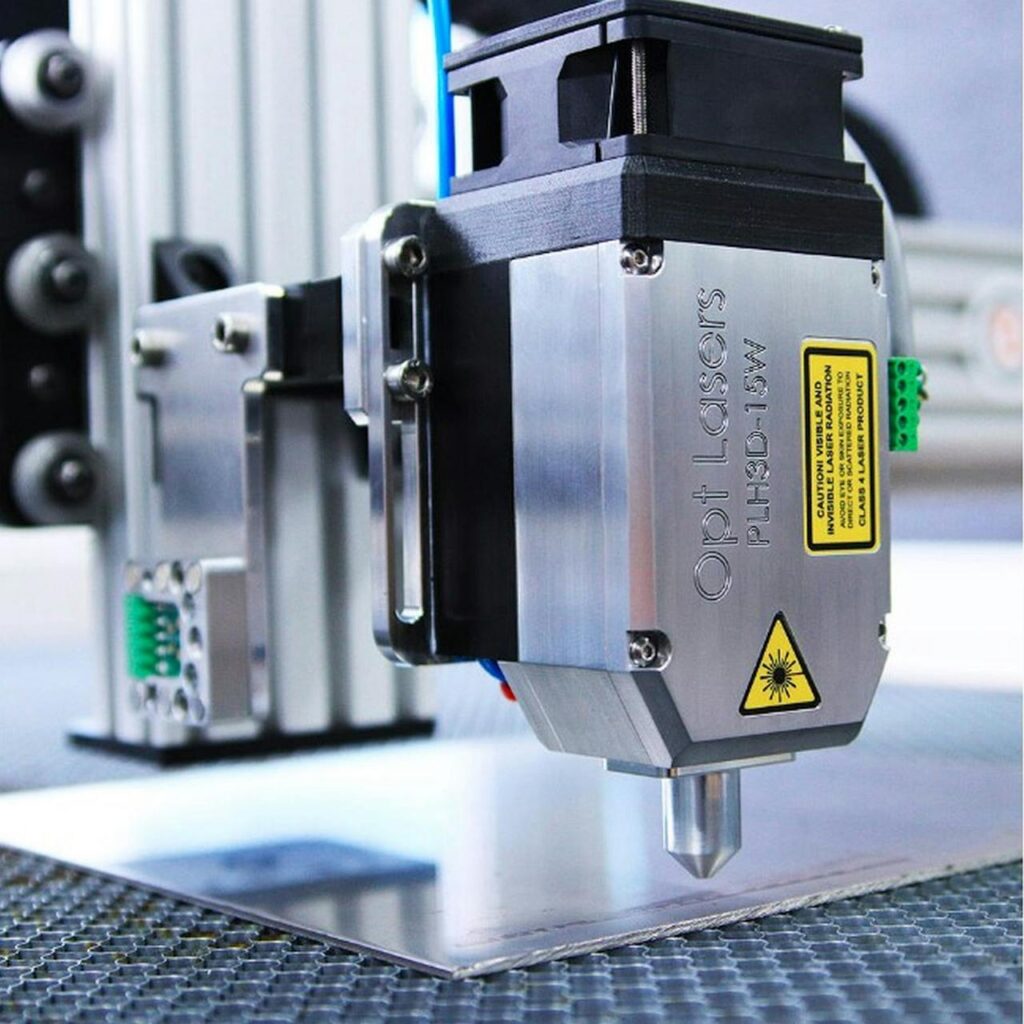

In 2025, the demand for fast, precise, and permanent product identification is higher than ever—and that’s where laser marking machine shine. Whether you’re in manufacturing, electronics, automotive, or medical industries, investing in a laser marking machine offers a competitive edge. This advanced technology delivers high-speed, non-contact marking on a wide range of materials with exceptional durability and clarity. With a growing emphasis on traceability, automation, and eco-friendly production, understanding the advantages of laser marking machines is essential for making smart, future-ready investments. In this guide, we break down the top benefits that make laser marking a must-have solution for modern businesses.

Here Are The 7 Advantages Of Using A Laser Marking Machine

High precision and accuracy

Laser marking machines deliver unmatched precision and accuracy, making them ideal for industries that require fine details and complex patterns. Whether marking micro-components in electronics or intricate logos on surgical tools, laser technology ensures clean, consistent, and exact results every time. In 2025, advancements in beam quality and software control allow for pinpoint accuracy with virtually zero deviation.

This is especially beneficial for applications involving serial numbers, barcodes, and QR codes, where clarity is crucial for traceability. Unlike mechanical or ink-based marking systems, laser machines maintain their precision over long-term use, with no physical contact or tool wear involved. If you’re looking for high-resolution results with superior repeatability, a laser marking machine is the wise choice for boosting both quality and compliance in your marking operations.

Permanent and durable marks

One of the most significant advantages of a laser marking machine is the ability to create permanent, high-contrast marks that withstand time and harsh conditions. Unlike ink, paint, or labels that can fade, peel, or rub off, laser marks are engraved or etched directly into the material’s surface. In 2025, industries like aerospace, medical, and automotive will rely on laser marking for lifetime traceability, ensuring critical parts are always identifiable.

These marks are resistant to heat, chemicals, moisture, and abrasion—making them perfect for environments where durability is non-negotiable. Whether it’s a serial number on a metal component or a QR code on plastic packaging, laser marking offers long-term readability without additional maintenance.

Non-contact and non-damaging process

Laser marking is a non-contact, non-damaging process, making it ideal for delicate, sensitive, or finely finished materials. Unlike mechanical engraving or stamping, which physically press or cut into surfaces, laser marking uses a focused beam of light to alter the material without touching it.

This means there’s zero mechanical stress, no risk of deformation, and no need for clamping or fixturing—especially important in industries like electronics, jewellery, and medical devices. In 2025, laser technology has advanced to the point where you can mark ultra-thin metals, fragile plastics, or coated surfaces without compromising structural integrity. This results in cleaner finishes, reduced rejects, and longer-lasting components.

Works on a wide range of materials

Modern laser marking machines are highly versatile and capable of marking a wide variety of materials with exceptional clarity and consistency. Whether you need to mark metals like stainless steel, aluminium, or brass or non-metals such as plastics, ceramics, glass, and composites—there’s a laser solution that fits. Fiber lasers are ideal for metals, UV lasers for plastics and heat-sensitive substrates, and CO₂ lasers for organics like wood, leather, and glass.

In 2025, multi-material processing is more important than ever, especially for manufacturers producing complex assemblies or varied product lines. Laser systems easily switch between materials with minimal setup, offering fast, flexible marking for any application. This versatility reduces the need for multiple machines and streamlines production. With the ability to handle nearly any surface, a laser marking machine offers a one-stop solution for all your marking needs.

Low operating and maintenance costs

When it comes to long-term value, laser marking machines stand out for their low operating and maintenance costs. Unlike traditional marking systems that require ink, solvents, or regular part replacements, laser systems are virtually maintenance-free. Fiber lasers, in particular, offer life spans of up to 100,000 hours and require minimal servicing. In 2025, energy-efficient designs and air-cooled systems will reduce power consumption and eliminate the need for complex cooling infrastructure.

There are no consumables to replace, no ongoing chemical purchases, and minimal downtime—making laser marking a cost-effective solution for high-volume operations. Even better, automated calibration and self-cleaning optics further reduce upkeep. Over time, these savings add up significantly, giving you a lower total cost of ownership.

Fast and efficient production

Speed is a key advantage of using a laser marking machine, especially in high-volume or automated production environments. Laser marking is significantly faster than traditional methods like dot peen or stamping, with some systems capable of marking hundreds of items per minute. In 2025, advanced galvanometer technology and real-time software control will enable ultra-fast marking with high repeatability and minimal cycle time.

This means more products marked per hour—and less time spent on setup, adjustment, or cleanup. Laser systems can be seamlessly integrated into automated lines or robotic systems, ensuring uninterrupted workflow and consistent results.

Eco-friendly and clean technology

Laser marking is one of the most eco-friendly marking technologies available in 2025. Unlike inkjet or chemical etching, laser systems don’t use inks, solvents, or hazardous materials, eliminating waste and reducing the need for harmful disposal practices.

This clean, dry process generates no by-products, fumes, or pollutants—making it safer for both operators and the environment. Modern laser systems are also energy-efficient and operate quietly, contributing to a cleaner, more sustainable workplace. With increasing regulatory and consumer demand for green manufacturing practices, investing in a laser marking machine supports your sustainability goals while boosting operational efficiency.

The Bottom Line

In 2025, a laser marking machine is more than just a marking tool—it’s a smart investment in precision, durability, and efficiency. With advantages like high accuracy, permanent marks, low maintenance, and eco-friendly operation, it outperforms traditional marking methods in every aspect. Whether you’re marking metals, plastics, or delicate components, laser technology offers unmatched versatility and cost-effectiveness. As industries push for faster production and sustainable solutions, laser marking stands out as the clear choice for forward-thinking businesses. If you’re looking to elevate your marking process, reduce long-term costs, and meet modern manufacturing demands, a laser marking machine is the way forward.